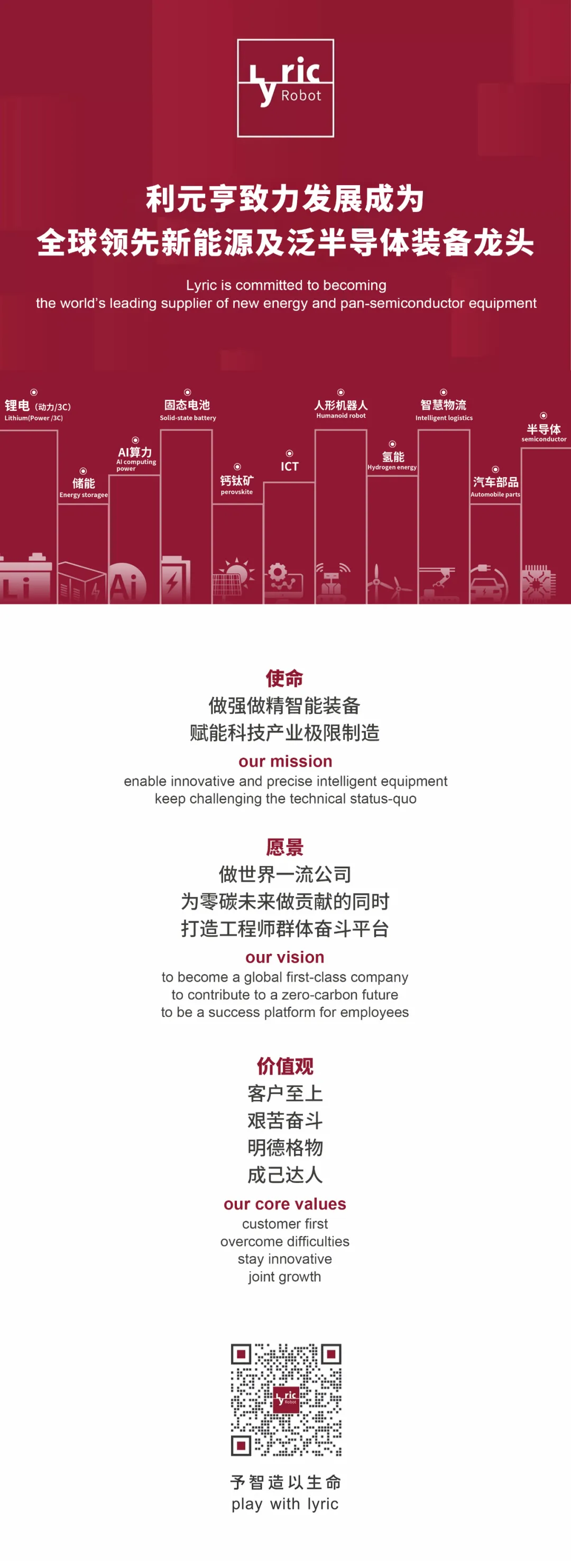

技术立业丨利元亨激光焊接在线检测设备:精准、高效、无损的“质量守护者”

在新能源、航空航天、汽车制造等高精尖领域,激光焊接已成为决定产品性能的关键工艺。然而,传统依赖人工目检或破坏性检测的质量控制方式,已难以满足现代制造业对效率、精度与可靠性的严苛要求。利元亨激光焊接在线检测设备应运而生,以其精准、高效、无损的监测能力,成为破解行业痛点的核心解决方案。

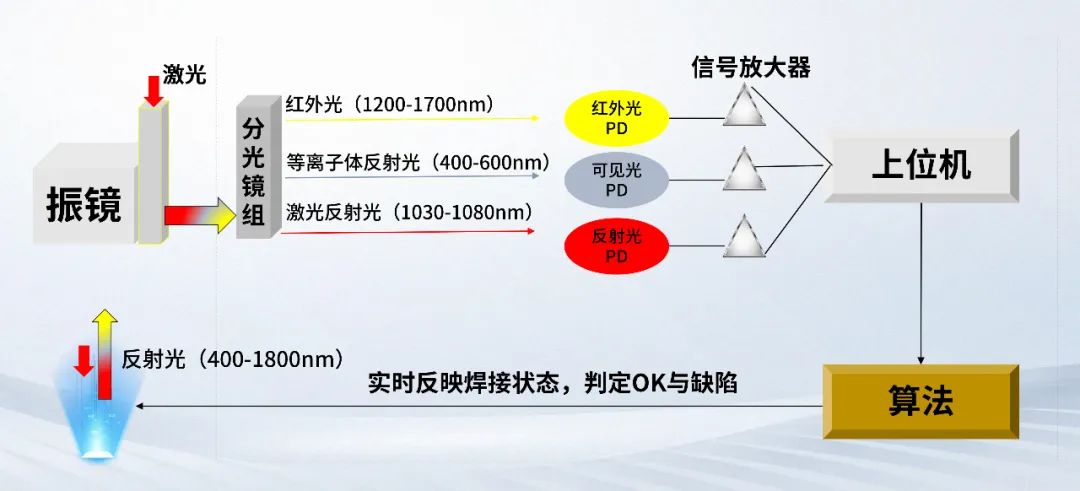

利元亨激光焊接在线检测设备通过捕捉激光焊接产生的400-1700nm波段弧光(含可见光、激光反射光、红外光),利用三通道分光技术实现精准监测:可识别离焦、污染、炸点、虚焊、间隙、材料污染、功率波动等20余类典型焊接缺陷,并输出可视化曲线与判定结果。

• 可见光通道(400-600nm):实时解析熔池形态变化;

• 激光反射通道(1030-1080nm):监测功率稳定性与焦点偏移;

• 红外通道(1200-1700nm):识别材料吸收差异与表面污染。

随着新能源、航空航天、汽车制造等领域对焊接质量提出更高要求,激光焊接在线检测设备正成为智能工厂的标准配置。选择一套真正有效的在线监控设备,不仅是技术升级,更是企业在智能制造时代抢占先机的关键一步。

Lyric Laser Welding Online Inspection Equipment: The Precise, Efficient, and Non-Destructive 'Guardian of Quality'

In high-tech industries such as new energy, aerospace, and automotive manufacturing, laser welding has become a critical process determining product performance. However, traditional quality control methods relying on manual visual inspection or destructive testing can no longer meet the stringent demands of modern manufacturing for efficiency, precision, and reliability. Lyric’s laser welding online inspection equipment emerges as the solution, offering accurate, efficient, and non-destructive monitoring capabilities to address these industry challenges.

Lyric's laser welding online inspection equipment captures arc light (including visible light, reflected laser light, and infrared light) generated during the welding process across the 400-1700nm wavelength range. Leveraging triple-channel spectral splitting technology, it enables precise real-time monitoring, identifying over 20 types of typical welding defects—such as defocusing, contamination, spattering, cold welds, gaps, material impurities, and power fluctuations, while providing visualized data curves and diagnostic results.

• Visible Light Channel (400-600nm): Real-time analysis of molten pool dynamics and morphology changes.

• Laser Reflection Channel (1030-1080nm): Continuous monitoring of power stability and focal point deviation.

• Infrared Channel (1200-1700nm): Detection of material absorption variations and surface contaminants.

Technical Parameters: The New Engine of Intelligent Manufacturing

Core technical parameters:

Response wavelength range: 400-1700nm

Luminous flux: 12.7mm

Sampling frequency: 0-100KHz

Supply voltage: 24V

Missed detection rate: 0

False detection rate: <0.5%

Market Pain Points: Solving Three Major Industry Problems

Uncontrollable quality

Traditional testing methods are backward and unable to feed back the welding status in real time. With a millisecond-level response mechanism, the system can detect abnormalities during the welding process and issue timely alarms, thus avoiding batch defects.

Persistently high costs

Destructive testing leads to massive material waste. The system realizes non-destructive testing, reducing quality inspection costs by over 60%.

Difficulty in closing the loop of process optimization

There is a lack of effective data to support process adjustments. The system supports aggregated analysis of historical data, automatically identifies trend changes, and assists engineers in precise parameter tuning.

As the new energy vehicle, photovoltaic, and aerospace industries demand higher welding quality standards, laser welding in-line inspection equipment is becoming a standard feature in smart factories. Choosing a truly effective online monitoring system is not just a technological upgrade—it’s a critical step for enterprises to gain a competitive edge in the era of intelligent manufacturing.

发表评论